We work with our customers to develop solutions capable of meeting individual requirements in the semiconductor industry.

Our professional consulting service covers problem analysis, project planning, technical documentation and complete system solutions.

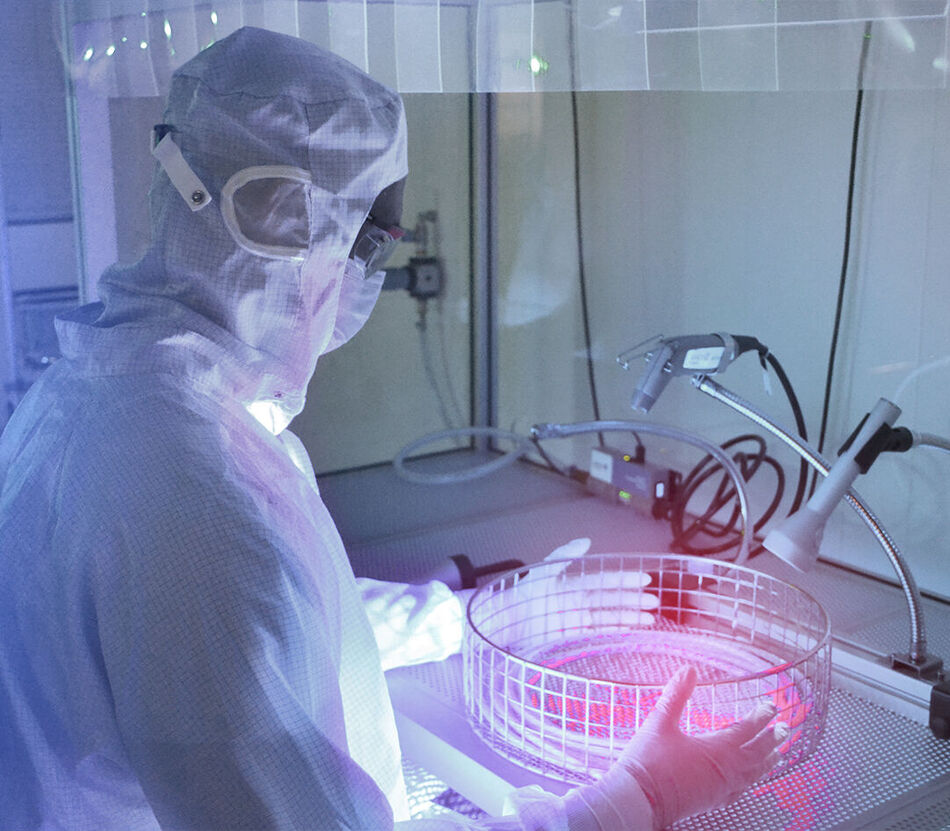

For the Semiconductor and Display market, BizLink installed a clean room footprint of over 2000 m² with different cleanliness grades in accordance with ISO 14644-1 class 5–9. This independent footprint enables the prevention of crosscontamination of forbidden materials in this industry and ensures not only a climate-friendly environment for the production of clean room application cables and cable systems but also health-friendly production for our employees.

Thanks to our team of highly qualified employees, we are always one step ahead in the development of new products. We get involved with technological innovations early on and provide high-quality, competent and reliable solutions to implement our customers’ requirements.

Quality

BizLink Quality Management

The outstanding quality and reliability of our products and solutions are what makes our name a brand. With these attributes we are setting standards across the global market. The certification of our quality management systems is rigorously documented. Along with continual improvement, we specifically focus on our product and process quality as well as responding promptly to customer and market demands as corner-stones of our quality policy. For, after all, it is our customers who set our quality targets.

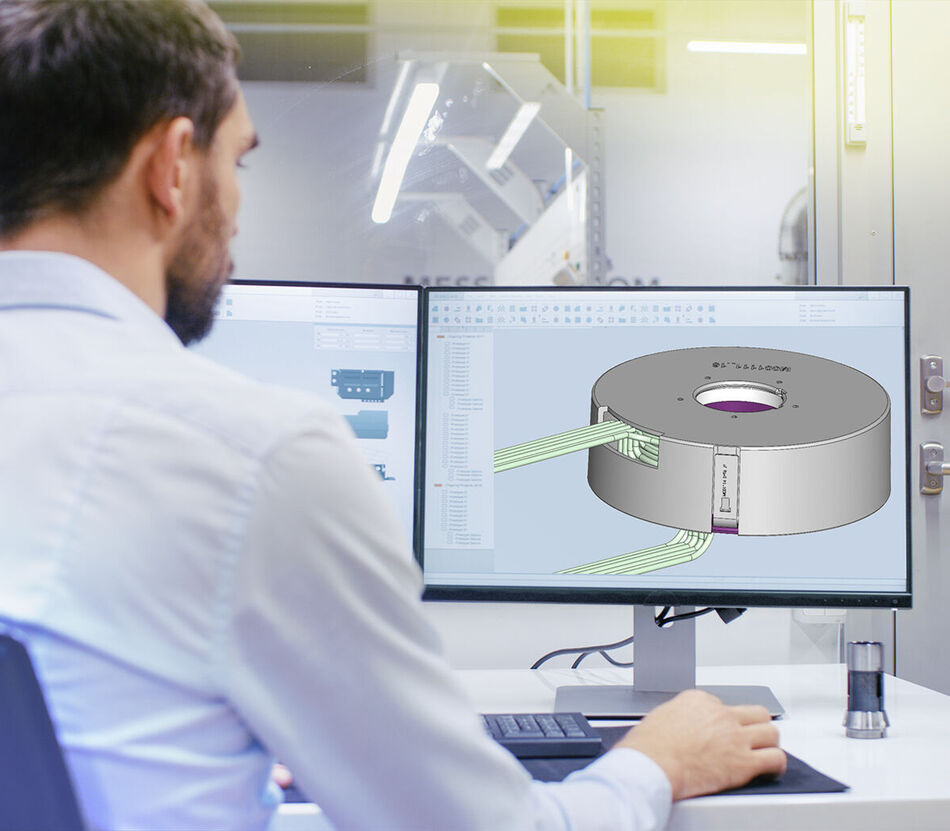

Each application is analyzed by our engineers to better understand specific requirements. BizLink uses selected products for outstanding customization, when specific elements are required.

Monitoring

A consistently high level of quality is vital for our products. This means that the entire process at BizLink, from planning a product through to its completion, is constantly monitored. Our quality management system is DIN ISO 9001:2008 certified. These are constantly monitored. For the manufacture and sale of products for the North American market we are able to apply over 650 different UL styles.

Cable Approvals

Due to our stict quality management all clean room cables can be tested as follows, depending on customer requirements:

- IPA certified ISO 14644-1 (e.g. HPF: EBK 41627)

- High vacuum (RGA) ISO 14644-15

- UL/CSA certification

- Low outgassing test at ChemTrace

Quality Tests

In addition to elective external certifications, such as ChemTrace and Fraunhofer IPA, all elocab clean room cables are manufactured and tested according to our strict clean room specifications.

Environment

BizLink Environmental Management

We do not regard financial success and environmental responsibility as a contradiction in terms. That’s why protecting the environment is an intrinsic element of our corporate activities. Our DIN ISO 14001 certified environmental management system enables us to ensure that our environmental policy is effectively implemented.

BizLink Energy Management

Sustainable action will secure the future of our company. In line of economic, environmental and social requirements, we take our social responsibility. We are committed to the continual improvement of energy efficiency and sustainable resource utilisation.

Further information:

Website of BizLink-Group

Research & Development

Customised Connectors

Varying demands are made on the connection system depending on the material, nominal cross section and components used. We will provide you with support as early as the concept phase, identify critical marginal conditions with you and develop prototypes.

Optimised Production Processes

Constant further development of existing production processes is essential for making special cables. For example in the area of miniaturisation we are developing production technologies which in themselves resemble small-scale cable production lines. In such specialised manufacturing cells we make products that achieve high packing-density with optimum electrical properties.

Our production processes also must constantly be adapted due to ever increasing data rates and transfer speeds. Thanks to our innovative BizLinkZELL® foaming technology to refine the core dielectric, the transfer properties of a cable are optimised whilst achieving very small diameters.

Material Development

BizLink develops and uses jacket and insulation materials that meet the demand for a high degree of safety and durability, both indoors and outdoors, mobile or fixed, on land, in water or also under extreme conditions of use.

Along with thermoplastics, elastomers and thermoplastic elastomers this also includes particularly resilient fluoropolymers as well as silicone rubber. We are also familiar with processing glass fiber and mica materials.

10.09. – 12.09.2025

SEMICON Taiwan 2025

TaiNEX 1 & 2, Taipei Nangang Exhibition Center, Taipei,, Taiwan

To Organizer