Test Procedures

Numerous quality tests during production enable us to ensure the quality of our cables and cable systems.

Drag Chain Test Centre

Ensuring Long-Lasting Dynamic Requirements

We are always investing in our device equipment in order to live up to our slogan “BizLink – The Quality Connection” and thereby to cater to the needs of our customers. The long-lasting tenacity of our cables is tested in various processes in order to prove their long service life.

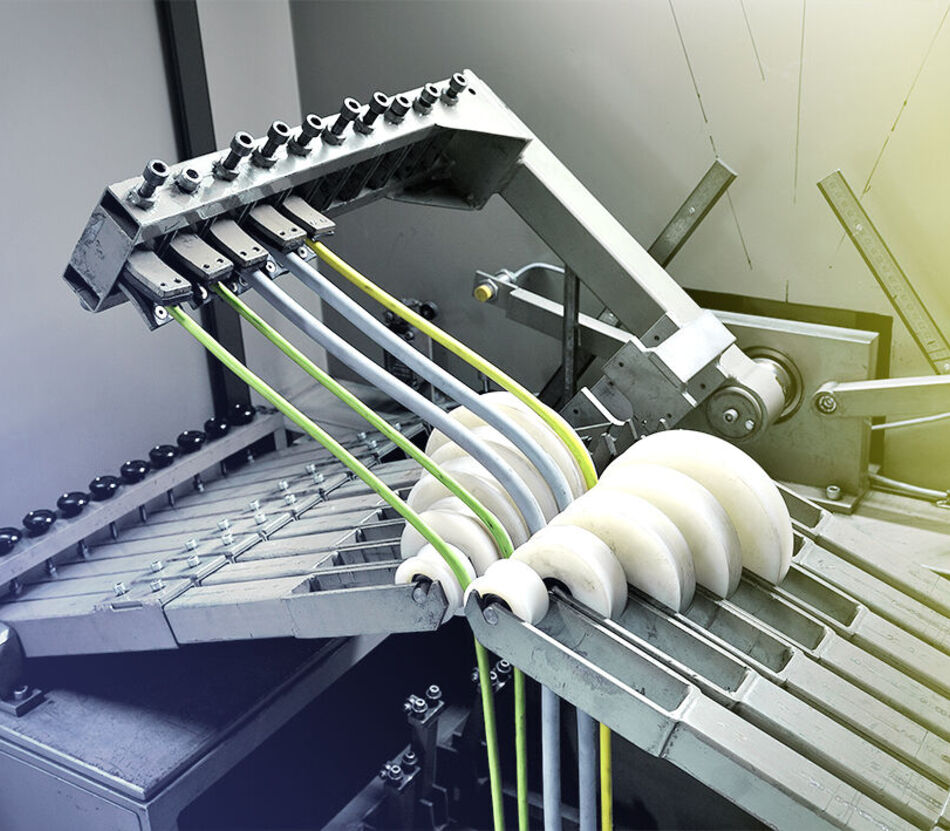

Drag Chain Tests

Our test routes have different travel ranges, accelerations and travel speeds. Each test system can test up to 40 cables over the equivalent of several years. The longest traverse path measures 50 m.

Torsion Tests

In different torsion and torsional bending machines, the cables are tested for twisting and traction around their own axes. They are subjected to a torsional movement of up to +/– 360° in length from 0.3 to 1 m.

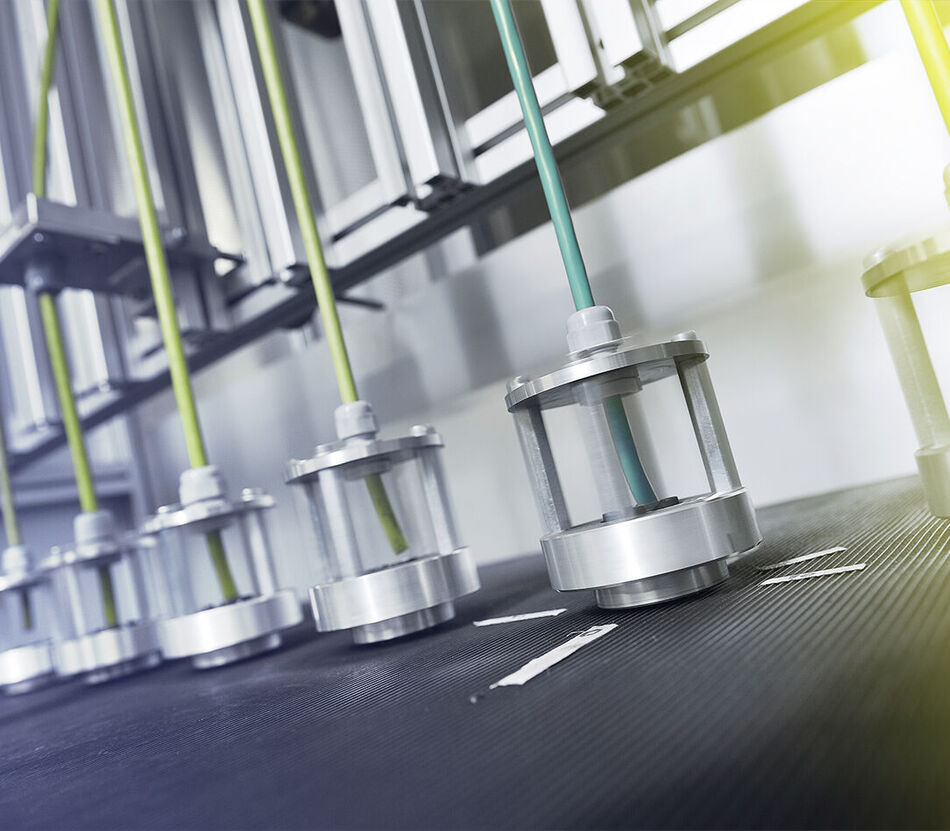

In cable production

Our cables are manufactured to the highest standards of quality and are subject to constant and rigorous testing throughout the manufacturing process as well as at the final stage. Process-related data is constantly monitored “inline” throughout the production process.

It is also our standard practice to conduct spot checks testing cable properties either according to specific standards or on the basis of customer requirements.

On request, individual test records are made available.

For our customers that signifies: secured quality.

Examples of the properties tested include:

- Wall thickness

- Diameter

- Eccentricity of the conductor

- Adhesion and stripping properties

- Abrasion

- Resistance to extreme cold or heat

- Shearing and tensile stress

- Reversed bending tests (1)

- Flexlife tests (2)

- Torsion tests (3)

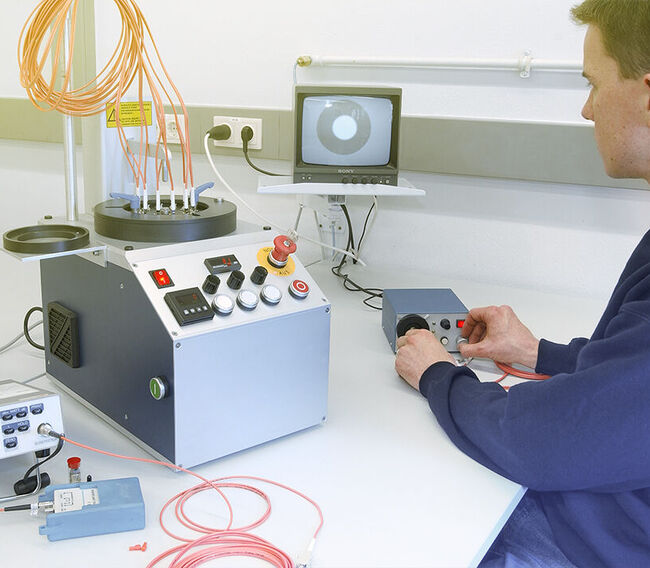

Cable Assembly

All the cable systems leaving our factories will have been subjected to complete and extensive testing. We can also use customised testing and measuring methods.

Final Inspection

Visual check for any obvious deficiencies, electrical test for continuity (network test), pin assignment, connector examination, insulation, electric strength; high-frequency parameters such as insertion and return loss, mode conversion and skew using test fixtures specially optimised for each particular product.

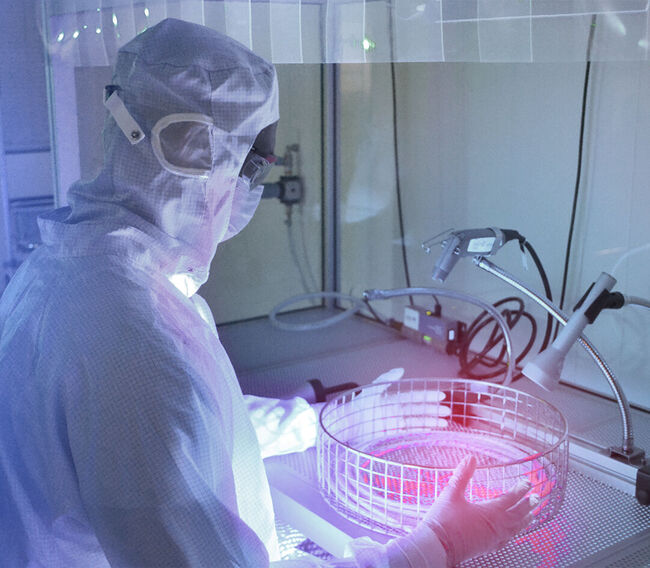

Micrograph Laboratory

Micro sectioning test with subsequent documentation; archiving of crimping results at the request of the customer. Software-based micrograph generation and analysis functionality with information on the compression level, crimp height, surface area/nominal cross section calculation.

Tensile Strength Test

Similar to the micrograph test, this is also a destructive test where the withdrawal force at which the cable disengages from the cable connection is determined and documented before commencing.