Front End Production

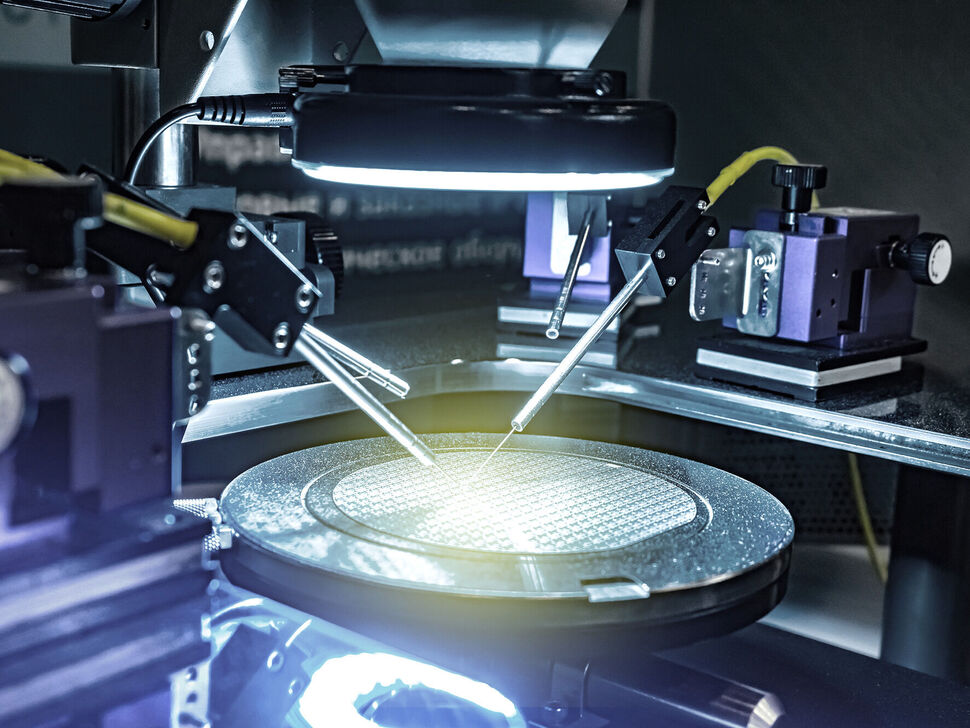

Testing (High Voltage)

BizLink Offers Cables and Cable Assemblies for Test Applications in Clean Rooms.

Pioneers in semiconductor wafer inspection equipment already trust in our solutions. Our 20 kV high voltage cables with outer jacket made of low friction PTFE tape have great performance during test procedures for Wafers. These systems test the connections of the Wafer by high voltage impulses.

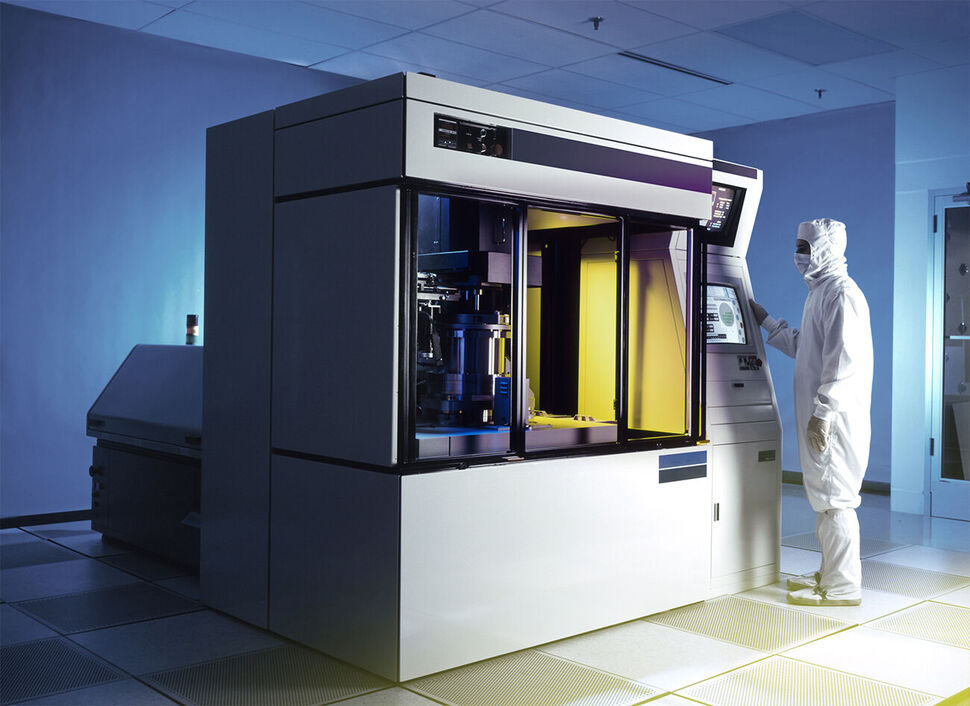

Electron-Beam Lithography

Silicon Direct Write, Compound Semiconductor, and Mask Making are Manufacturing Processes with High Technical and Cleanliness Requirements.

Our customer is the leader in designing and manufacturing of electron-beam lithography. They fulfill all these requirements with elocab clean room cables. The customized design of elocab cables always are the specific solution which the customer needs.

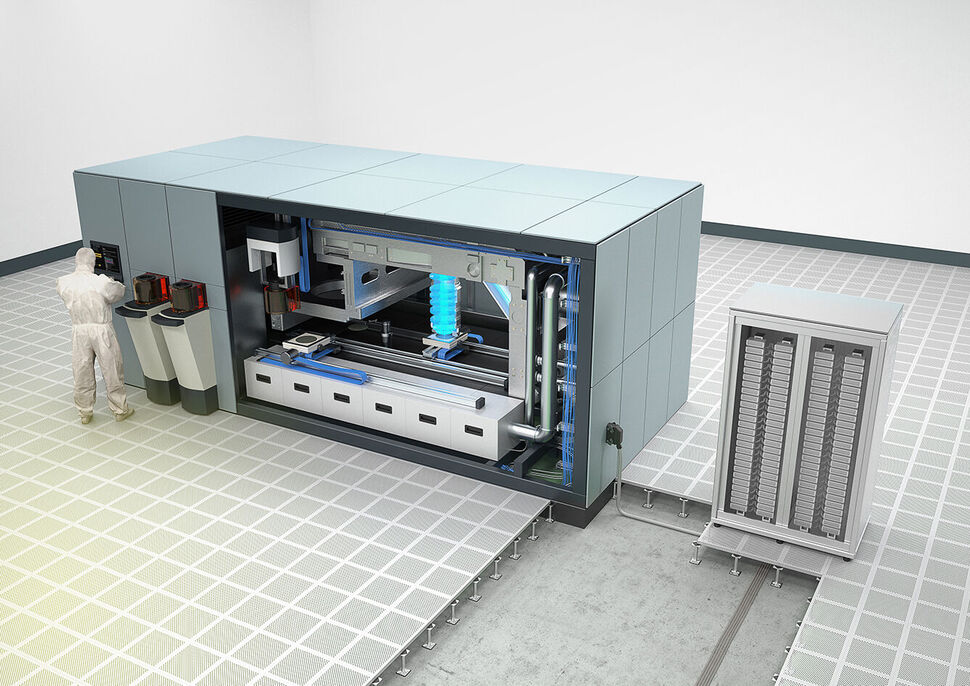

Measuring Systems

BizLink’s Customer is a World Market Leader in Multidimensional Measuring Technology and Manufactures Measuring Systems for Adjusting Mirrors in Lithographs.

Therefore, BizLink delivers power, control and data cable assemblies. The clean room round cables are optimized for comfortable installation and are equiped with special low outgassing jacket materials with improved mechanical strength. BizLink engineers customized cable bundles are good for up to 60 meters making it easy for clean room installation.

Etching Equipment

Leading SMT machinery manufacturer and partner to the world's leading semiconductor companies trust in elocab clean room cables.

Applications

Typical applications are front-end etching equipment. The laminated High Performance Flex Cables enable faster, more complex and precise etching equipment with a smaller footprint.

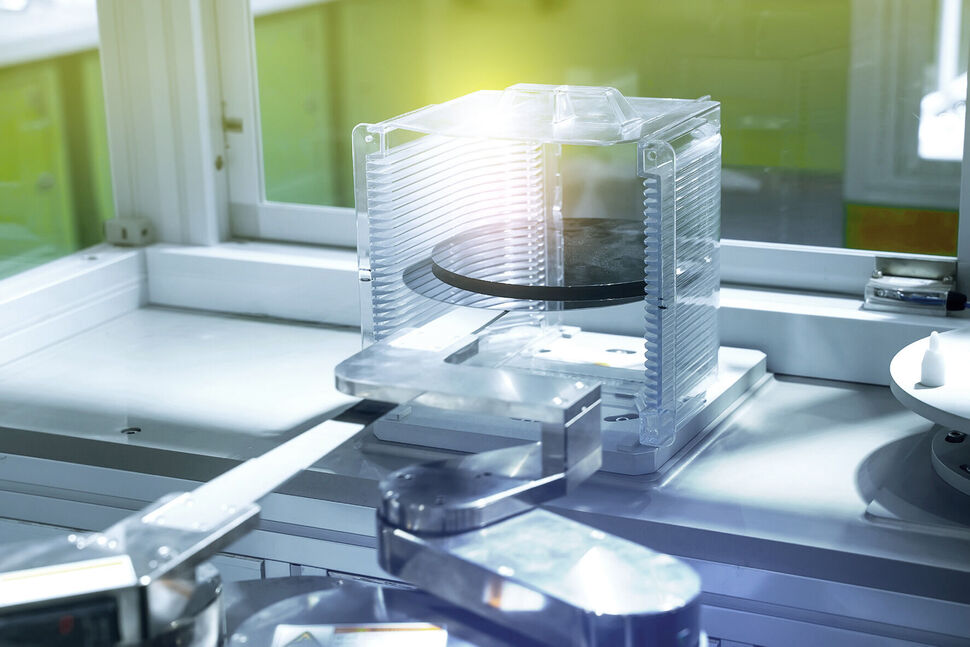

Cable for Wafer Platform

elocab’s High Performance Flat Cables fulfil requirements in challenging environments such as highly sensitive and precise movements.

Applications

These often occur in semiconductor and display frontend and backend installations and planar platforms. High Performance Flat Cables are the ideal solution for step-and-scanapplications, wafer process control, structuring of wafers and laser-based heat treatment of wafers. Some leading suppliers for high precision and high dynamic motion technology now use this and trust in elocab solutions.

Wafer Handling Robots

World leader in vacuum robotics, electric motor technology and leading manufacturers of wafer handling equipment use elocab cables and cable assemblies for the full spectrum of wafer handling robotics.

Applications

There are solutions for robotics for thin or bonded wafers and specialized wafer carriers. Robots for various uses around arc welding (including spot welding), handling, assembly, painting, transfer of liquid crystal panels, and transfer of semiconductor wafers are equipped with elocab clean room cables. Especially the laminated High Performance Flex Cables perfectly fit for these kind of applications.